Zinc Selenide (ZnSe)Double-Convex Lenses

Zinc selenide (ZnSe)material has a high tolerance to thermal shock, making it to to be an optical material for high power CO2 laser systems. The hardness is only 2/3 of multispectral grade ZnS, the material is soft and prone to scratching, and the material has a large refractive index, so it needs to be coated with a high hardness anti-reflective film to protect it and obtain a high transmittance. In common spectral range, the scattering is very low.

Zinc Selenide (ZnSe)Double-Convex Lenses with two convex spherical surface that includes an incident surface and an emitting surface, characterized by a longer focal length at the middle of the lens surface and a shorter focal length at the end of each lens surface. And it’s often widely in various optical systems and equipment, such as lasers, optical instruments, spectral analysis instruments, etc.

Our company can provide Zinc Selenide (ZnSe)Double-Convex Lenses with diameters from 2-300mm.and thicknesses from 0.12-60mm (accuracy up to 20-10, 1/10L@633nm),coating AR, BBAR, AF or upon request.

Technical parameters of Znse Double-Convex Lens

Diameter | 2-300mm |

Focal length | 15-5000mm |

Thicknesses | 0.12-60mm |

Dimension tolerance | +0/-0.1mm |

Thickness tolerance | ±0.1mm |

Surface quality (scratch & dig) | 60-40, 40-20, or better |

Surface accuracy | λ/2, λ/4 or better |

Parallelism | 3' ,30'' |

Bevel | 0.1~0.3mm x 45 degree |

Clear aperture | >85%,>90% |

Coating | AR coating or cutom |

Material properties of ZnSe

| Physical Properties | |

| Crystal Structure | Cubic |

| Density[g/cm3] | 5.27 |

| Resistivity[Ω.cm] | ~1012 |

| Melting Point [℃] | 1525 |

| Chemical purity[%] | 99.9996 |

| Thermal Expansion [1/K] | 7.1*10-6@273k |

| 7.8*10-6@373k | |

| 8.3*10-8@473k | |

| ThermalConductivity [J/k.m.s] | 18.0@298k |

| Specific Heat Capacity [J/g.K] | 0.339@298k |

| Knoop Hardness [kg/mm2] | 110 |

| Bending strength [Mpa] | 55 |

| Young's Modulus [GPa] | 67.2 |

| Poisson's coefficient | 0.28 |

| Optical Properties | |

| Transmission Range | 0.5-22μm |

| Refractive index inhomogeneity[△n/n] | <3*10-6@632.8μm |

| Absorption coefficient [1/cm] | 5.0*10-3@1300nm |

| 7.0*10-4@2700nm | |

| 4.0*10-4@3800nm | |

| 4.0*10-4@5250nm | |

| 5.0*10-4@10600nm | |

| Thermal light coefficient[1/k,298-358k] | 1.07*10-4@632.80nm |

| 7.0*10-5@1150nm | |

| 6.2*10-5@3390nm | |

| 6.1*10-5@10600μm | |

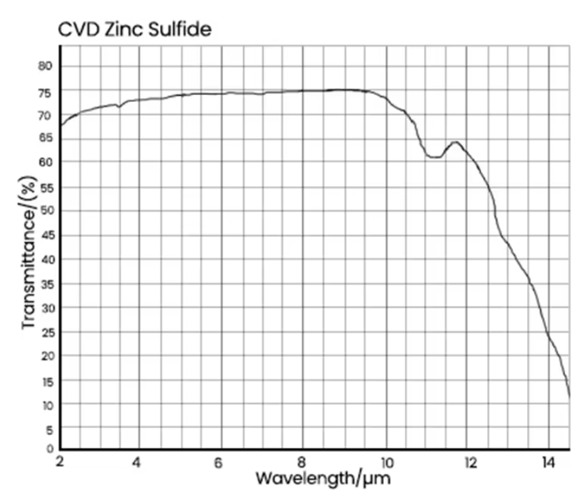

Transmission curve

Zinc selenide has high transmittance in the 600nm-16um and is commonly used in thermal imaging, infrared imaging, and medical systems. Also, due to its low absorption, zinc selenide is particularly suitable for use in high-power CO2 lasers. It should be noted that zinc selenide is a relatively soft material (Nucleus hardness 120) and is easily scratched, so it is not recommended for use in harsh environments.